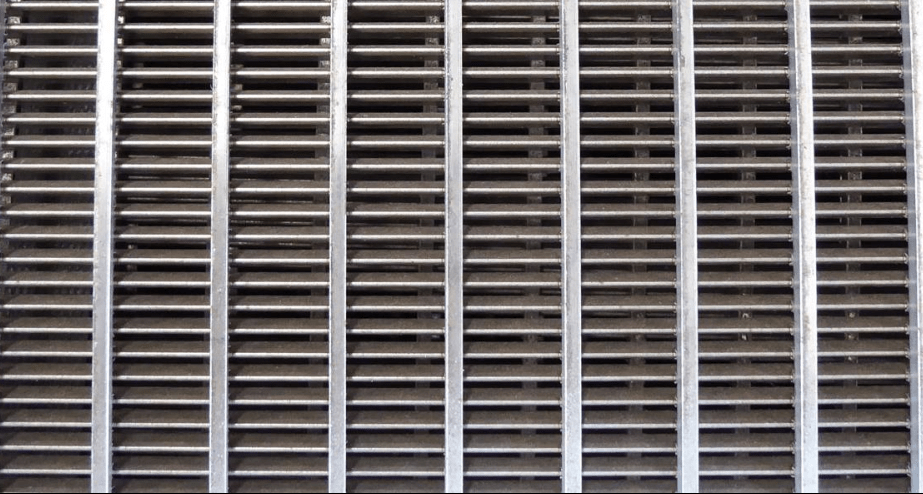

A metal mesh that is extensively used in filtration, screening, desliming, and dehydration operations for filtration and sieving is a Wedge wire screen. The wedge wire screen has high load carrying capacity, rigidity, and strength, and it can be made into various shapes according to rigid screening filters.

The wedge wire screen is a versatile screen that can be used for multiple purposes due to its amazing characteristics such as clogging resistance and toughness. The formation of a mesh or slit that is suitable for different applications is by arranging the wedge wires in an equal interval in a triangular shape.

The wedge wire screen has support profiles and surface profiles. To understand both the profiles in detail, the surface profile has v-shaped wires and these wires are welded and wrapped upon the support profiles. Since it forms the slot using which the filtrate flows, the distance is controlled very precisely between the surface profiles. The position of the surface profile that is the V-shaped wire determines the direction of flow concerning the support profiles. The wedge wire screen has two types, they are either flow-in-to-out or flow-out-to-in.

Advantage of wedge wire screen

- As compared to other screens, the wedge wire screen has a large circulation area.

- The effective retention of the filter medium is ensured by the high precision of the wedge wire screen and uniform filter slots.

- The small aperture between wedge wire forms an even wedge-shaped cross-section, this helps to make sure that it has no dead-ends and hence offers exceptional resistance to block and it’s easy to blow wash or backwash.

- The wedge wire screen can stand up to high-pressure drops and has a distinguished mechanical strength.

- Wedge wire screen is made up of stainless steel wires (SUS304,316L) with high-temperature resistance and strong corrosion-resistance performance and it can also adapt to a harsh environment.

- It maintains a firm accuracy of filtration and can also be reused over and again and it works reliably.

- It can also adapt itself to the various forms of fluid direction with its notable strength, high-pressure resistance, and large flow performance.

Features of wedge wire screen

High durability and high strength

The wedge wire screen features high durability and strength as compared to filters like perforated plates, wire mesh, or filter cloths. Depending on the material and usage environment, a wedge wire screen can be used for a long time with no definite end without any replacement, this reduces the running cost. There are also wedge wire screens that are produced using special materials like duplex stainless steel or titanium. The reasons behind all of these benefits are:

- Formation of the screen having a wire diameter larger than the slit is possible.

- Due to its smooth screen surface, the degree of water remains constant.

- The material used is stainless steel wires (SUS304,316L).

Reduced clogging, improved dewatering

The most important feature of a wedge wire screen is its triangular shape. Because, as the solid passes through it, the point of contact is small and the tips of the slit get widened in such a way that solids are not likely to clog. Even if they get clogged, the backwashing effect is so strong that it results in excellent maintainability.

Conclusion

You will see wedge wire screens in many machine parts such as dewatering machines, filtration equipment, etc. Because of its processing variations and wide range of applications, wedge wire screen is manufactured in different shapes like cylindrical, flat, and conical.